CNC Laser Cutting Machine

- TRUMPF TruLaser 3030

-

- Laser Power: 3 kW (CO₂ Laser)

- Working Area: 3000 mm (X-axis) x 1500 mm (Y-axis) x 115 mm (Z-axis)

- Maximum Material Thickness:

--Mild Steel: 20 mm

--Stainless Steel: 12 mm

--Aluminum: 8 mm - Maximum Workpiece Weight: 900 kg

- Positioning Speed (Simultaneous): 140 m/min

- Position Accuracy: ± 0.05 mm

CNC Press Brake

- Yawei CNC Press Brake (Model: PBA-110/3100)

-

- Bending Force: 1100 kN

- Bending Length: 3100 mm

- Distance Between Uprights: 2600 mm

- Throat Depth: 410 mm

- Ram Stroke: 215 mm

- Die Setting Height: 520 mm

- Approach: 160 mm/s

- Bending: 10 mm/s

- Return: 130 mm/s

- Main Motor Power: 7.5 kW

- Oil Tank Volume: 250 L

- Overall Dimensions (L×W×H): 3560 × 1550 × 2620 mm

Welding Machines

- 1. Colton TIG Welding Machine, 400 Amp

-

- Output Current: 400 Amps

- Input Supply: Three Phase, 400V AC

- Duty Cycle: 60% at 400 Amps

- Pulse Duty Cycle Range: 1% - 100%

- Control Modes: 2T / 4T

Welding Machines

- 2. Colton MIG Welding Machine, 400 Amp

-

- Model Name/Number: iMIG 400S

- Welding Current Range: 50–440 A

- Input Voltage: 415V, Three Phase

- Duty Cycle: 300 A at 60%

- Open Circuit Voltage: 18–51 V

- Wire Diameter Compatibility: 0.8–1.2 mm

Welding Machines

- 3. Warp TIG Welding Machine, 200 Amp

-

- Output Current Range: 10–200 Amps

- Input Voltage: 220/240V AC, Single Phase

- Duty Cycle: 60% at 200 Amps

- No-Load Voltage: 56V

- Power Factor: 0.93

- Efficiency: 85%

Welding Machines

- 4. Accurate Spot Welding Machine, 20 kVA

-

- Power Rating: 20 kVA

- Input Voltage: 220V/415V AC, 50/60Hz

- Duty Cycle: 50%

- Weldable Materials:

--Mild Steel: Up to 3.25 mm thickness

--Stainless Steel: Up to 3.25 mm thickness

- Electrode Force: Adjustable via pneumatic system

- Cooling System: Water-cooled electrodes and holders

- Throat Depth: Standard 460 mm (customizable)

EOT Crane

- M.S.G. Fabrications 5 Ton Single Girder EOT Crane

-

- Lifting Capacity: 5 Tons

- Crane Type: Single Girder Electric Overhead Traveling (EOT) Crane

- Span: Customized based on application requirements

- Lifting Height: Varies as per operational needs

- Hoist Mechanism: Electric wire rope hoist with precision control

- Travel Mechanism: Motorized end carriages with geared motors

- Control System: Pendant control with optional remote control

- Power Supply: Typically 415V, 3-phase, 50 Hz

- Safety Features: Overload protection, limit switches, emergency stop

- Applications: Ideal for material handling in workshops, warehouses, and industrial facilities

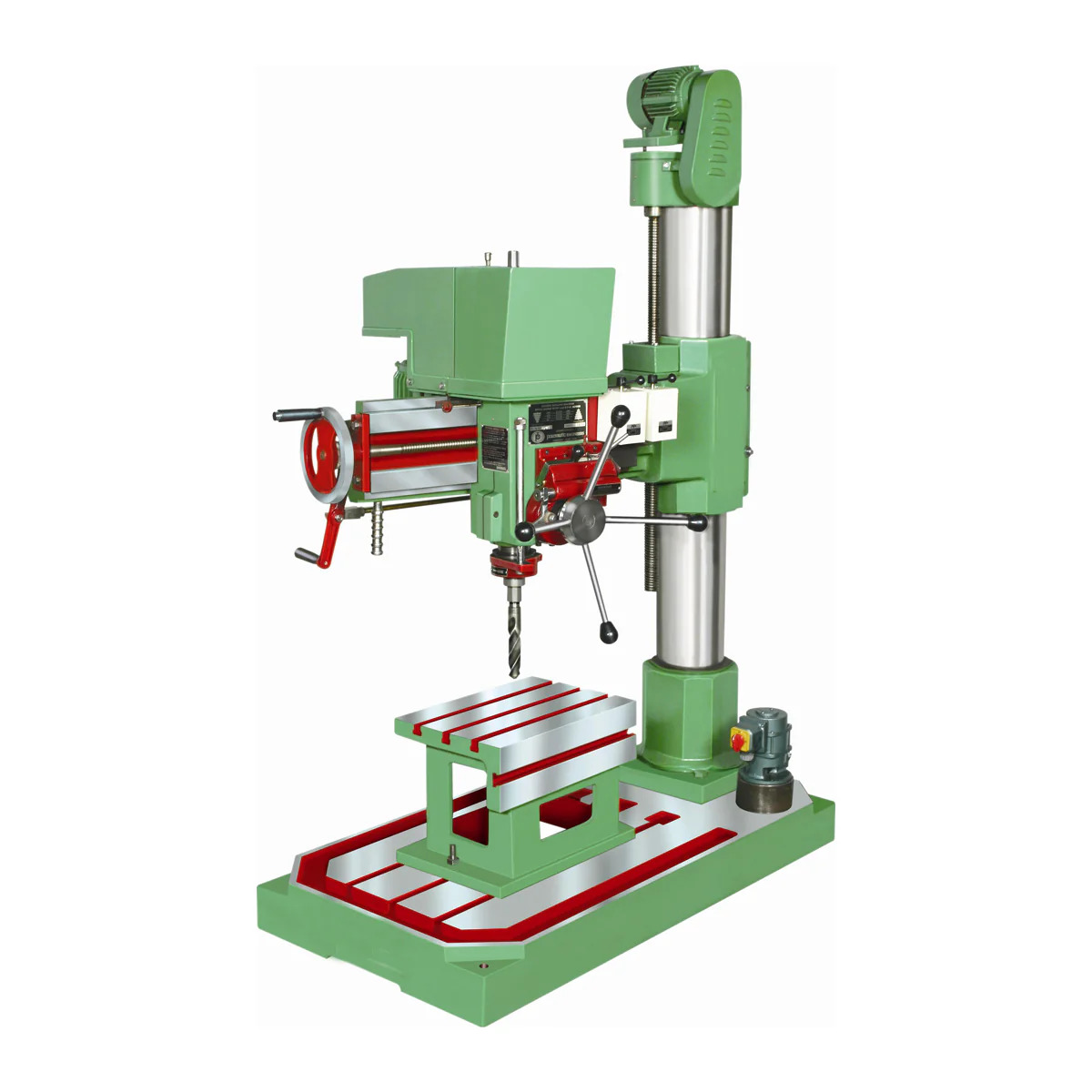

Drill Machine

- 1. Apex Drill Bit 1-1/4" Diameter

-

- Type: High-Speed Steel (HSS) Twist Drill Bit

- Diameter: 1-1/4 inches (31.75 mm)

- Shank Type: Straight or Tapered Shank (depending on specific model)

- Overall Length: Varies based on model

- Flute Length: Varies based on model

- Point Angle: 118 degrees standard; other angles available for specific applications

- Material Compatibility: Designed for drilling into materials such as mild steel, aluminum, brass, and plastics

- Coating: Options include uncoated, black oxide, or titanium nitride (TiN) for enhanced performance and longevity

Drill Machine

- 2. Apex Radial Drill 1-1/4" Diameter

-

- Drilling Capacity:

--Mild Steel: 1-1/4 inches (31.75 mm)

--Cast Iron: 1-5/8 inches (41.28 mm) - Column Diameter: 9 inches (228.6 mm)

- Spindle Speeds: Typically 6 to 12 speeds, ranging from 40 to 1,920 RPM

- Spindle Taper: Morse Taper #4 or #5

- Motor Power: Ranges from 3 HP to 7.5 HP, depending on specific model

- Arm Travel (Vertical): Approximately 25 to 33 inches

- Distance from Spindle to Column: Minimum: 13 inches; Maximum: 43 inches

- Table Size: Approximately 28 x 19 inches

- Drilling Capacity:

Bend Saw Machine

- Bharat 7" Circular Band Saw

-

- Lifting Capacity: 5 Tons

- Cutting Capacity: 7 inches (178 mm)

- Blade Size: 3/4 inch x 93 inches

- Blade Speeds: Four-speed options: 80, 130, 180, and 285 SFPM (Surface Feet Per Minute)

- Motor Power: 3/4 HP, 115V, Single Phase

- Machine Type: Horizontal/Vertical Band Saw

- Dimensions (L x W x H): Approximately 50" x 20" x 45"

- Weight: Approximately 400 lbs

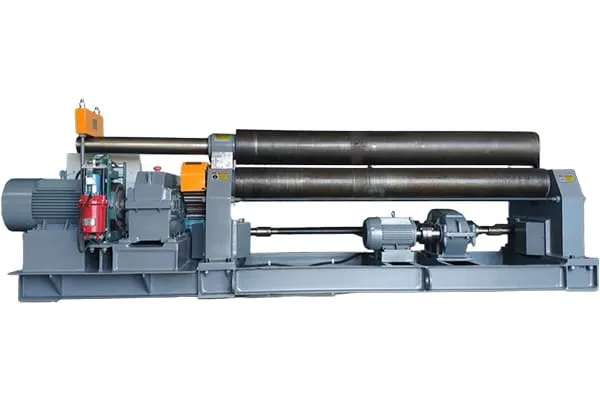

Rolling Bending

- Mechanical Pre-Pinching Plate Rolling Machine

-

- Bending Capacity: Suitable for plate thicknesses ranging up to 20mm

- Working Width: Available in widths up to 2500mm

- Roll Configuration: Three-roll design with movable bottom rolls for pre-pinch and bending operations.

- Material Compatibility: Capable of rolling materials such as mild steel, stainless steel, and aluminum.

- Operation Mode: Mechanical drive system with planetary gearboxes for enhanced torque and efficiency.

- Construction: Robust welded steel frame ensuring structural stability and durability.

- Pre-Pinching Capability: Designed to minimize flat ends by performing edge bending before rolling.

Lathe Machine

- Ajay Lathe – 4’-6”

-

- Swing Over Bed: Approximately 9 inches (229 mm)

- Distance Between Centers: 4 feet 6 inches (1372 mm)

- Spindle Bore Diameter: Approximately 1.5 inches (38 mm)

- Spindle Speed Range: Typically 70 to 2000 RPM

- Tailstock Quill Travel: Approximately 4 inches (102 mm)

- Motor Power: Around 2 HP

- Bed Width: Approximately 7 inches (178 mm)

- Threading Capability: Supports a range of inch and metric threads

Leveled Bed Plate

-

- Material: High-quality cast iron, stress-relieved to minimize deformation

- Surface Flatness Tolerance: Up to 0.2 mm over the entire surface, ensuring precise measurements and operations

- Surface Finish: Machined to a fine finish, typically achieving a roughness average (Ra) of 3.2 micrometers

- Load-Bearing Capacity: Engineered to support heavy machinery and components, with load capacities tailored to specific industrial requirements

- Mounting Features: Equipped with T-slots or threaded holes for secure attachment of workpieces and fixtures.

- Thickness: 50mm

- Length: 2500mm

- Width: 1250mm

- Quantity: 2

- Applications: Ideal for material handling in workshops, warehouses, and industrial facilities